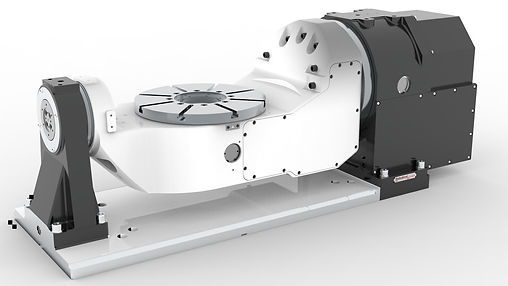

RTD SERIES

Maximize precision and efficiency in CNC machining with the RTD350’s zero-backlash, maintenance-free, high-performing rotary table.

.jpg)

OVERVIEW

RollerDrive Trunnion Tables: Sankyo’s two-axis trunnion tables feature our RollerDrive technology for both the tilt and rotary axes. The speed and accuracy of the tables make is suitable for many different applications. The zero-backlash nature of Sankyo’s RollerDrive technology has many advantages for both high-production machining applications and for contouring work.

FULL 360 ROTATION

ALLOWS MACHINING OF MULTIPLE SIDES OF A PART

BUILT FOR DURABILITY

EXCELLENT POSITIONING ACCURACY AND REPEATABILITY

RTD350 SPECIFICATIONS

Unit | Axis of Rotation | Tilt Axis | |

|---|---|---|---|

Table diameter | mm | φ 350

(T slot width 12mm) | - |

Work maximum diameter | mm | φ 530 | - |

Allowable work mass | kg | 300 | - |

Gear ratio | 1/60 | 1/96 | |

Maximum speed*1 | min-1 | 50 | 40 |

Operating range | deg | ± 360 | ± 120 |

Lubrication method | Oil bath (MOBIL SHC 629: 150 cSt) | Oil bath (MOBIL SHC 629: 150 cSt) | |

Lubricating oil amount | ℓ | ,f,,flb3 | 4 |

Product weight | kg | 600 | 600 |

Applicable servo motor | FANUC | αiS8/4000-B

(A06B-2235-B100) | αiS8/4000-B With brake

(A06B-2235-B400) |

Applicable servo motor | MITSUBISHI*2 | HG154S-D□□ | HG154BS-D□□ |

Continuous holding torque*2 | kg | 486 [432] | 778 [691] |

Maximum output torque*2 | N*m | 1021 [907] | 1633 [1452] |

Allowable work inertia | Kg*m2 | 9.93 | - |

PURE MOTION BY ZERO-BACKLASH TECHNOLOGY

Our CNC rotary tables are engineered with cutting-edge technology to deliver the accuracy, speed, and reliability that your business demands.

Designed for use with CNC machines, our tables are built to handle heavy loads and high-speed rotation, making them ideal for demanding industrial applications. Our state-of-the-art design and manufacturing processes ensure that our CNC rotary tables meet the highest standards for quality, durability, and precision.

Our CNC rotary tables are capable of performing a wide range of machining operations, including indexing, drilling, milling, and cutting. They offer unparalleled flexibility, allowing your business to tackle even the most complex parts with ease.

At Sankyo Automation, we understand that precision and efficiency are critical to your business operations. That’s why our CNC rotary tables are designed to help you maximize productivity and minimize downtime, giving you a competitive edge in today’s fast-paced business environment.

Whether you’re a large manufacturer, a machine shop, or a precision engineering firm, our CNC rotary tables can help you meet the demands of your customers with speed and accuracy. With our expert technical support and responsive customer service, you can be confident that you’re getting the best in the industry.